E-Beam Cables

The Tirupatiplastomatics difference

- Tirupatiplastomatics is famous for pioneering work in the elastomer cable segment in India. Since 1981, we have manufactured a wide range of elastomer cables that cater to various industry segments like railways, ship building, steel, defence and mining.

- We manufacture cables to various Indian and international standards like IS, IEC, VDE as well as Naval Defence specifications. We also customise products as per specific customer requirements.

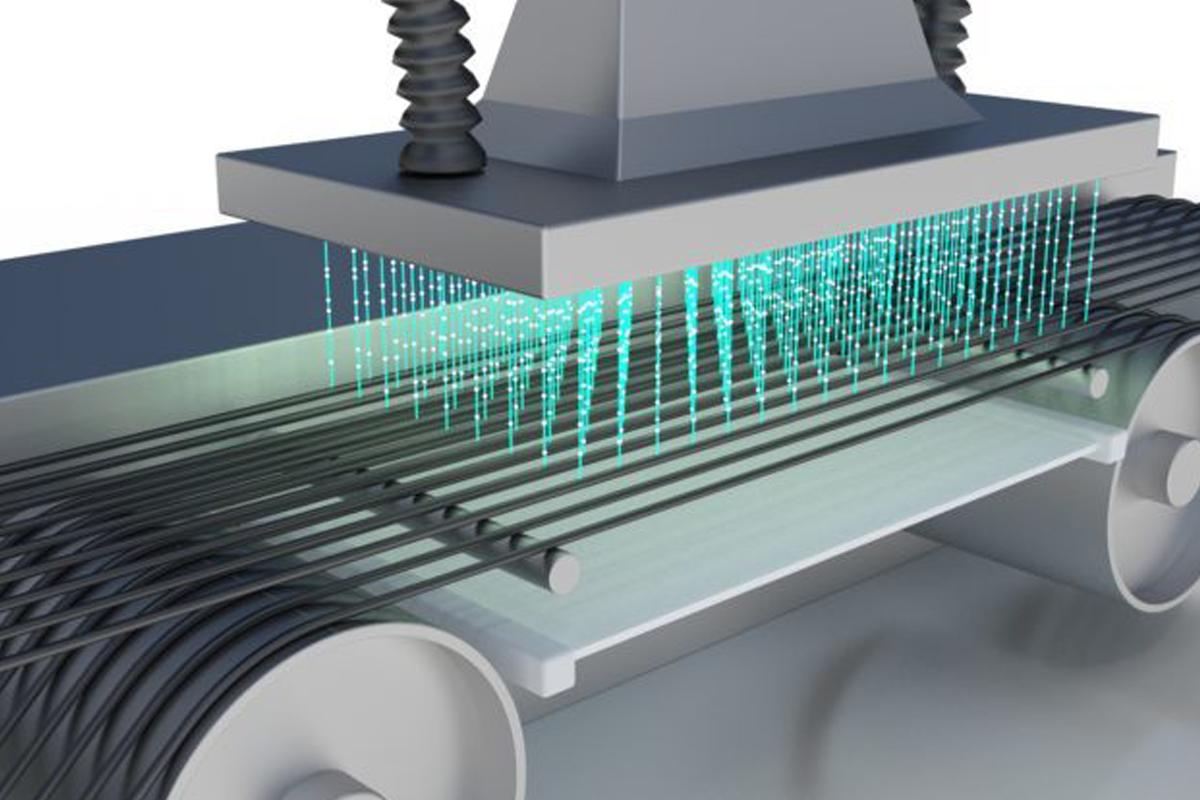

E-beam cables Features

The electron beam curing in “Wires and Cables” results into improvement of mechanical, thermal, chemical resistant, and other properties. The enhancement of properties results into improved physical properties with reduced thicknesses, higher temperature withstand capability, higher current carrying capacity and thus increased life of these cables. The e-beam cross-linking technology not only increases life and the current carrying capacity, but also prevents fires due to overload short circuits and thus saves precious lives and property.

Applications

Because of increased life and performance compared to conventional cables, e-beam cross-linked cables are being adopted in all high-tech applications such as

E-Beam Medical

The e-beam is able to penetrate medical devices and pharmaceutical products in their final shipping containers. The e-beam inactivates microorganisms either by causing microbial death as a direct effect of the destruction of a vital molecule or by an indirect chemical reaction. Advanced electronics precisely control the use of electrons in the sterilization of medical devices and pharmaceuticals. The process involves accelerating a beam of electrons to near light speed where it passes through a scan chamber and then transitions into a curtain of electrons. Materials moving through the chamber on a conveyor system are showered with these high-energy electrons, which penetrate the material with a precise, predetermined dose. As the largest contract electron beam provider in the U.S., we offer capacity for large volume processing and provide a team of experts to deliver support.

Railways

tirupatiplastomatics has a vast product range including all cables used by moving vehicles across railway, metro, coach and underground rail infrastructure. These are used for power, control, communications, heating and ventilation inside the vehicles.

Ship-Wiring

The most important reason for using undersea electrical cables is safety and reliability. Tirupatiplastomatics’s undersea power cables are specifically designed and built for demanding service applications. Submarine power cables are designed for various applications, typically offshore wind farms, the oil and gas industry, island connections, static tidal and wave power applications as well as lake and river crossings. Our experienced team offers cable design capabilities to meet the most challenging requirements of interconnection, export and infield (array) submarine cable projects.

Nuclear Plants

Radiation emitted by radioisotopes often consists of beta particles and photons. The beta portion can be simulated with e-beam. The use of medium-voltage electron beams is a powerful tool in these applications, as they enable the simulation of constant high radiation exposure while using the same energy levels (as the MeV is adjustable to your needs) that such materials would be exposed to. The variable dose rate ability of medium-voltage electron beams also enables year-long reactor exposures to be simulated in a matter of days or even hours.

Diamonds

Diamonds, in particular, possess unique properties that make them ideal for irradiation. Dan highlights, “One of the things that work out very well with diamonds is they’re extremely conductive. They transfer that heat really well.” This conductivity ensures that the heat generated during the irradiation process is efficiently distributed throughout the gemstone, minimizing the risk of damage.

Defense

The Electron Beam Welding process is used for demanding joining tasks in many low- and high-tech applications within some of the most sophisticated defense systems. The highly repeatable process ensures safe, reliable performance for short and long term operation in a wide variety of extreme conditions. The combined knowledge of PTR's engineering staff is available to contribute ideas based on decades long experience.

Solar Power

Tirupatiplastomatics introduced a range of solar cables for emerging PV-based renewable energy installations backed by 30 years of experience in the manufacture of elastomeric insulated cables. These cables are used for interconnecting solar panels, combiner boxes and inverters in dry or damp conditions as well as in harsh environments exposed to ultraviolet sunlight radiation. These can be installed in open trays and in ducts or conduits. E-beam crosslinked solar cables offer numerous benefits for use in solar power systems. These cables are more resistant to temperature extremes, UV radiation, and chemical degradation, making them suitable for use in a variety of outdoor environments.

Client testimonial

Mr. Ovijeet Das

Overseas Infrastructures Alliance (OIA) India Pvt. Ltd.

“After the delivery of the cables against one of our RURAL ELECTRIFICATION (RE) project in Mozambique, TIRUPATI PLASTOMATICS TEAM was very apt in rendering the on-site training support related to installation aspects to our staff people which is exemplary and made our task lot more easier. We appreciate their POST SALES SUPPORT which was not a part of our contract agreement.”

Mr. I.P. Sharma

IRCON International Limited

“QUALITY is of paramount importance to our company and we are quite satisfied with the on-field performance of TIRUPATI PLASTOMATICS cables installed in our project”

Mr. Bharat Kulkarni

Hitachi Rail STS

“During the Pre-shipment inspection, we realized that the quality of workmanship of TIRUPATI PLASTOMATICS make cables is of highest quality. Their labs are fully equipped to perform all the ACCEPTANCE TESTS which were desired from our side. We would come back for the repeat purchase of the similar cables”

Ms. Nirmal

Delhi Metro Rail Corporation (DMRC

“Our Experience of buying the cables for our Metro Project had been very satisfying as they are operationally performing well in line with our desired standards. We vouch for the technical prowess of TIRUPATI PLASTOMATICS make cables.”

Dedicated Customer Terms & An Agile Service

Our worldwide presence ensures the timeliness, cost efficiency and compliance adherence required to ensure your production timelines are met.

Download Brochures

LV Cable Catalog MV Power Cable Catalog MVCC CatalogRequest a Quote

Complete control over products allows us to ensure our customer receive the best quality price and service. we take great pride in everything that we do in our factory.